What do Die Cast Associates Do?

- We operate and manage furnaces and machines that melt metal and cast our parts.

- We check and confirm parts for quality.

- Move & Load product to and from machines for our other departments to assemble the compressor.

- All operators will run 2 machines and have a continued commitment to safety and quality.

What is Die Tooling?

We are like mechanics, we work on molds, replace components, and check function ability.

What is the work environment like?

- Think of it as a “non-air-conditioned garage mechanic shop”- it is hot in summer and cool in winter.

- We work around furnaces to melt aluminum to cast the housings.

- We must wear 100% cotton clothing & long-sleeve shirts due to working around furnaces.

- We have 12 machines and furnaces running at all times (each machine has 3 robots).

- Hearing protection is required and provided.

- We constantly work with graphite & hydraulic oil.

- It will get on you when you are changing hoses or dies and cleaning the machines.

- All areas do a focus clean for 2 machines per day.

- This must be done to maintain the machines to avoid build-up underneath that could destroy the machine.

What are shifts like?

- Day shift & Evening shift work starting at 7am or 7pm.

- 12 hour shift is typical, overtime is a requirement of our job.

- Saturdays may be scheduled when we do not meet production goals.

What are the physical requirements of the job?

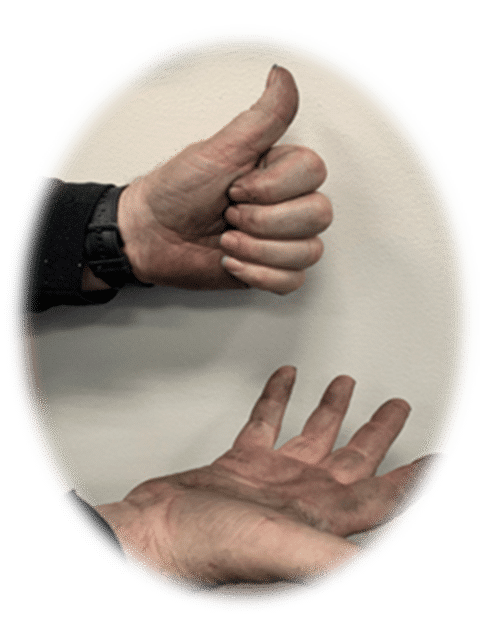

- Constantly: Stand, sit, walk, use hands to handle/grasp/feel, manipulate fingers by using hand tools.

- Occasionally: Lift and/or move at least 40lb, reach with hands from waist to shoulder level, reach with hands from shoulder level to overhead, stoop kneel, crouch, and/or crawl, climb & balance (climbing stairs, ladders, etc.)

- Others duties within normal limits: Normal to corrective vision (important for part quality inspection), communicate effectively by talking and hearing, use hands and finders to operate computer keyboard and other office equipment.